Ultimax Tie-Down Anchors: top quality hardware with design distinction and special function for specific conditions and applications.

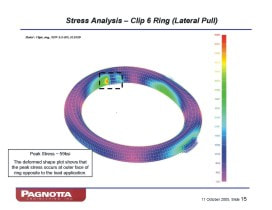

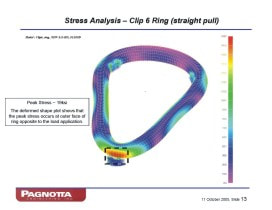

We started out by looking at what our customers need and where existing products fail to fill the bill. We conducted regulatory research to define product standards (and discovered that although there are government regulations for many aspects of cargo transport, there are none that specifically address the anchors to which cargo is tied.) We did extensive materials research and testing. We explored scores of design solutions and had final prototypes evaluated using FEA (Finite Element Analysis) by consulting engineers who count NASA among their clients. We tested production-ready Ultimax Tie-Down Anchors in our own facility using stringent, verifiable standards and procedures. And we contracted with US manufacturers to supply high quality parts.

We started out by looking at what our customers need and where existing products fail to fill the bill. We conducted regulatory research to define product standards (and discovered that although there are government regulations for many aspects of cargo transport, there are none that specifically address the anchors to which cargo is tied.) We did extensive materials research and testing. We explored scores of design solutions and had final prototypes evaluated using FEA (Finite Element Analysis) by consulting engineers who count NASA among their clients. We tested production-ready Ultimax Tie-Down Anchors in our own facility using stringent, verifiable standards and procedures. And we contracted with US manufacturers to supply high quality parts.

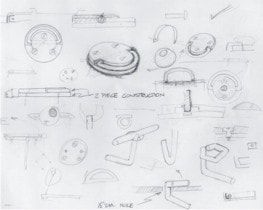

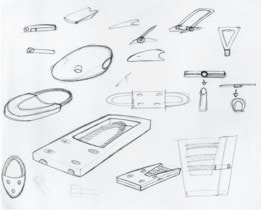

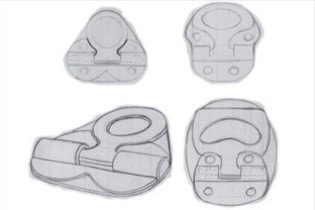

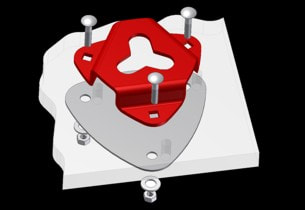

concept design

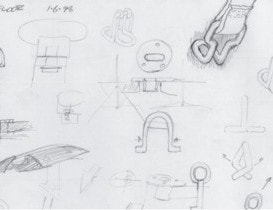

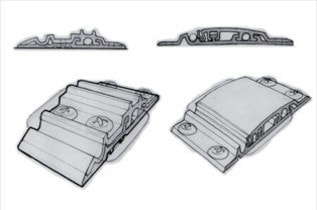

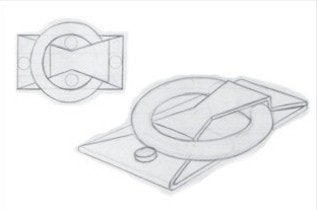

concept development

|

|

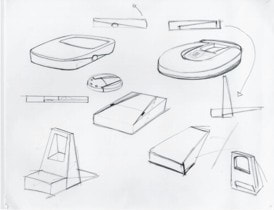

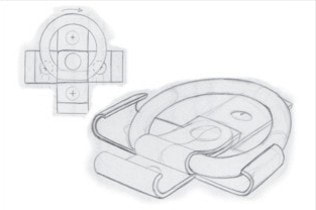

Design Refinement

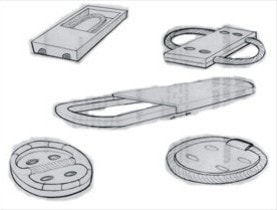

After evaluation of the prototypes, aesthetic and functional revisions were made. Base plates and overall forms received styling modifications and a few of the tie-down anchor designs were eliminated from the product group. Detailed illustrations /renderings of each anchor were then produced using 3D-Studio Max software, complete with hardware and tie-down straps.

After evaluation of the prototypes, aesthetic and functional revisions were made. Base plates and overall forms received styling modifications and a few of the tie-down anchor designs were eliminated from the product group. Detailed illustrations /renderings of each anchor were then produced using 3D-Studio Max software, complete with hardware and tie-down straps.

engineering

|

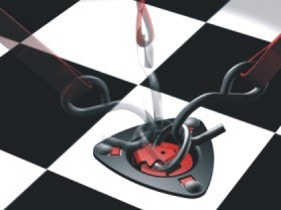

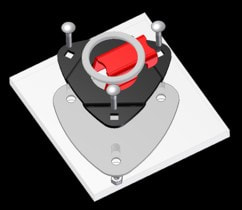

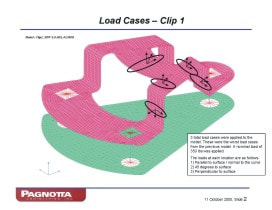

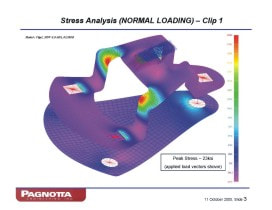

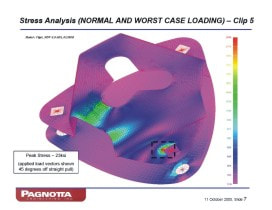

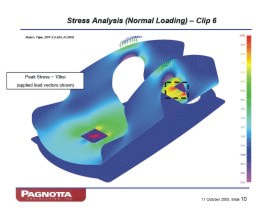

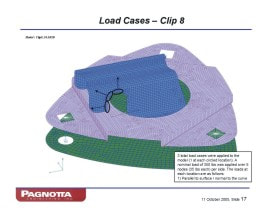

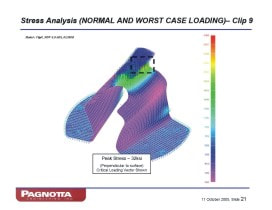

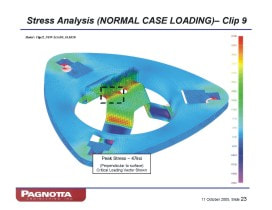

FEA Testing

3D CAD models were evaluated using FEA (Finite Element Analysis) by consulting engineers who count NASA among their clients. FEA illustrated, when stresses and varying loads are applied to each anchor, how each tie-down anchors will react. |

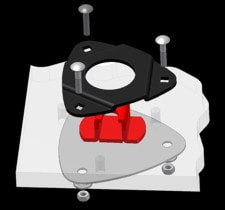

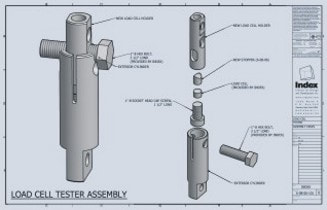

Destructive Testing

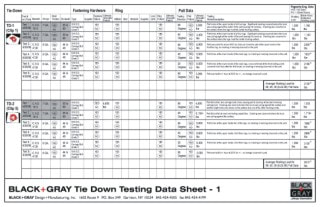

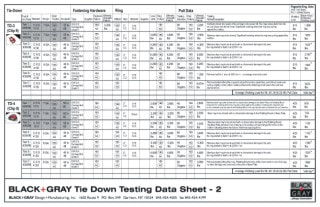

Using a load cell testing tool and hydraulics to exert pull force/ loading, pre-production samples were installed and stressed at different loads and angles. All sample anchor models were stressed to the point of failure. Additional tests of anchor ‘mounting-surface’ materials were performed to understand failure limits of common trailer materials. Detailed logging of the testing results, including applied pull strengths and angles and a description of the failure of each component or assembly was recorded. Subsequent analysis of the test data was used to calculate the working load limits for each model Ultimax Tie-Down Anchor.

Using a load cell testing tool and hydraulics to exert pull force/ loading, pre-production samples were installed and stressed at different loads and angles. All sample anchor models were stressed to the point of failure. Additional tests of anchor ‘mounting-surface’ materials were performed to understand failure limits of common trailer materials. Detailed logging of the testing results, including applied pull strengths and angles and a description of the failure of each component or assembly was recorded. Subsequent analysis of the test data was used to calculate the working load limits for each model Ultimax Tie-Down Anchor.

production

|

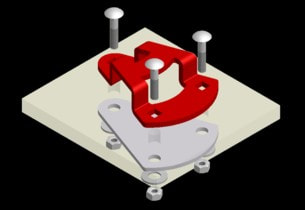

Production Drawings

Final production drawings were produced from the 3D CAD models and prepared for fabrication/production. |

|

|

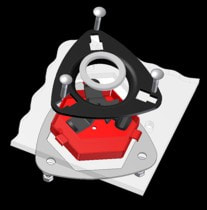

Production Parts

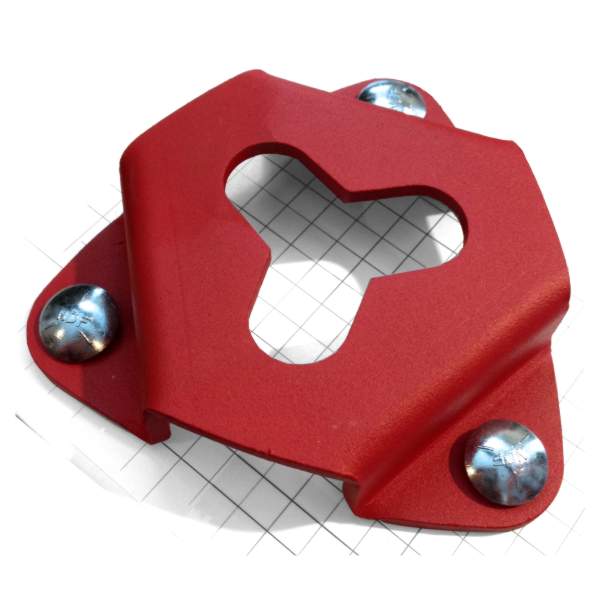

Made in USA Production components were fabricated, heat treated, powder coated and assembled into 6 tie-down anchor products, each with different features and load ratings. |

|

Supporting Documentation

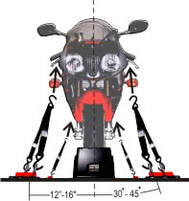

Supporting documentation was produced, specifying installation and assembly instructions, working load ratings, and instructions for the proper usage of tie-down anchors when used for motorcycles. |

|

|

Graphics, Packaging and Labeling

The ‘Ultimax’ product name was selected, graphics and logo were developed. An efficient common packaging approach was developed for all 6 anchor styles that clearly presents the product to consumers and provides sufficient space for labeling and contained installation hardware. |

|

Completed Product

The Ultimax Tie-Down Anchor line of products include: |