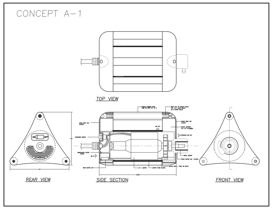

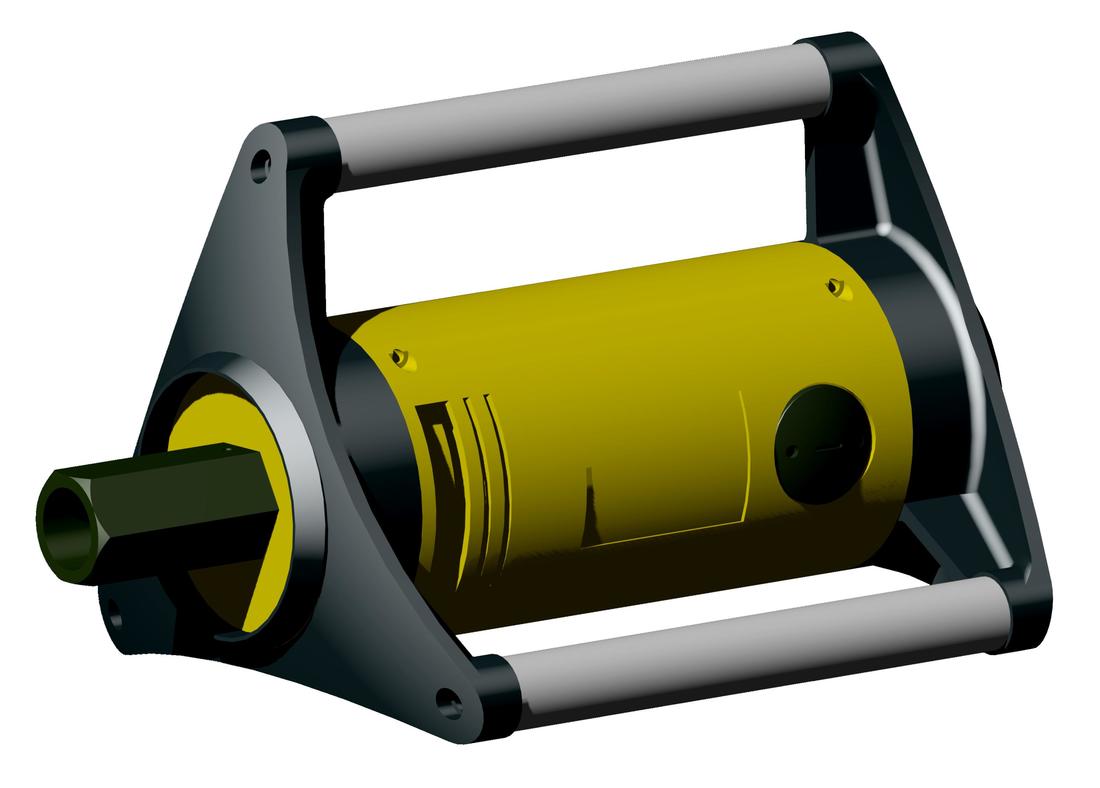

A unique concept for a Concrete Vibrator focused on use/ergonomic and manufacturing efficiency goals. Design includes common flexible molded end caps, common aluminum extruded handles and two piece injection molded housing. Designed to house 1, 2 and 3 horsepower electric motors and incorporates a quick-disconnect feature for flexible shafts.

concept design

Competitive Research

Stow|Bomag’s two existing products, representing a low-cost cast and fabricated metal product, and a higher-end plastic double-insulated version.

Stow|Bomag’s two existing products, representing a low-cost cast and fabricated metal product, and a higher-end plastic double-insulated version.

Concept Sketches

For the first round of concepts, the client allowed for a “clean sheet of paper” in exploring ergonomics, manufacturing processed, and product usage issues.

For the first round of concepts, the client allowed for a “clean sheet of paper” in exploring ergonomics, manufacturing processed, and product usage issues.

|

As a large number of concepts were produced, triangular shapes demonstrated inherent advantages.

|

Some of the concepts were about combining a molded plastic housing with metal components.

|

Other concepts dealt primarily with handle configuration and how this affected ergonomics.

|

design development

|

Sketches

The client chose to pursue a triangular form for the product, whose multiple handles address the way the product is used in the field. |

This series of sketches explored the many possible ways the selected concept might be constructed. |

A set of common endcaps spanned by handles further defined the design. |

|

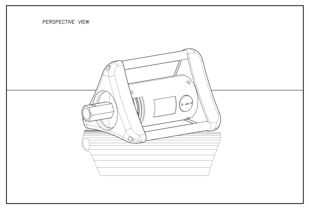

3D Modeling

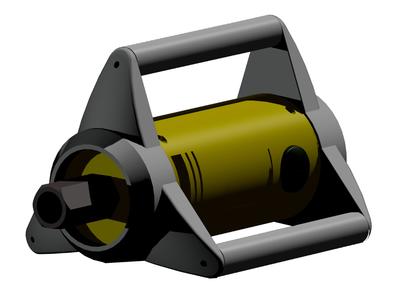

Three final design proposals were modeled and rendered for better visualization. |

Design Refinement

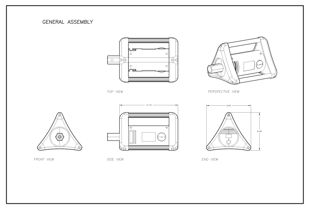

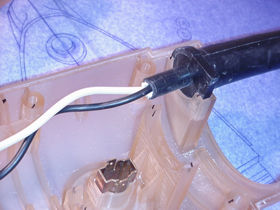

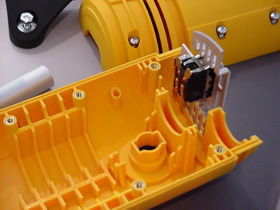

With the final design direction selected, development began into the details, switch locations, venting, and controls. 2D CAD Drawings

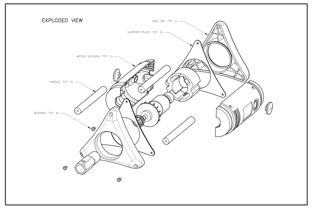

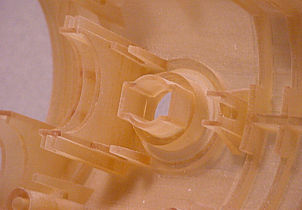

The details worked out, CAD documents and models were prepared to support the rapid prototyping process. |

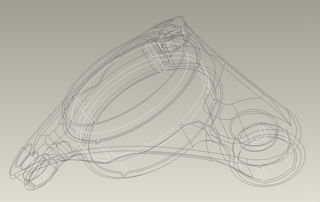

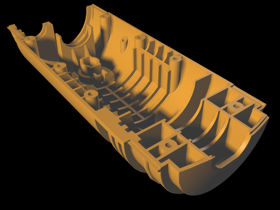

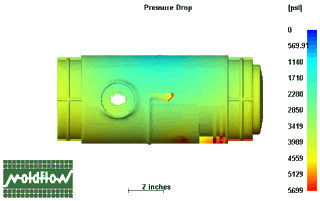

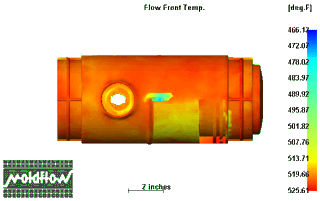

3D Parametric Modeling

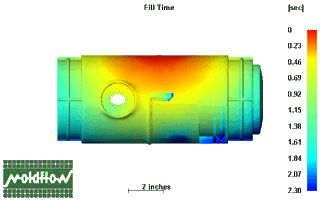

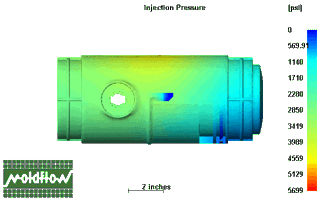

ProEngineer models were used for the rapid prototyping process and for engineering evaluation.

ProEngineer models were used for the rapid prototyping process and for engineering evaluation.

engineering | production

Urethane Castings