concept design

|

2002 - Hertz #1 Club Gold Directory Board

Designed and developed by IndexID in 2002, the existing Hertz #1 Club Gold Directory Board displays 40 names and stall numbers within each 4 ft. wide unit. Multiple units installed allow more names to be displayed. Designed using single color LED “strip” modules, each name display is limited to 14 characters and a 3 digit number. The Directory Board is an integral piece of equipment for Hertz business. |

2004 - Initial Design Directive

As display technology was evolving, in 2004, Hertz wanted to utilize flat panel LCD monitors for name displays in order to increase the number of names per display and reduce the number of Directory Boards required and have the ability to use and manipulate various media content. Several LCD monitor sizes, arrangements and graphic layouts were evaluated. |

2007 - Concept Sketches for Flat Panel LCD Integration

Based on available LCD monitor sizes and associated HVAC requirements, integration of the flat panel LCD monitors required modifications to the dimensions and construction of the Directory Boards. Installation of Directory Boards within Hertz facility spaces typically include parking garages which required some type of air conditioning unit installed in the base to keep the interior environment of the Directory Boards within the allowable operating temperature of the LCD monitors. |

2008 - Concept Sketches for Flat Panel LCD Integration

Additional concept sketches were created, moving away from the modification and use of the existing Directory Board enclosure, proposing a new LCD Directory Board Design. A 2x3 array with six 46” LCD monitors was selected as a design direction for the project, abandoning the use of the existing enclosure. |

|

Concept Renderings

Concept renderings were produced using 3D Studio Max, presenting different configurations, overall scale and sizes. The use of flat panel LCD monitors gives flexibility to the displays, adding color and unlimited possibilities for information and content, which can be easily controlled and updated. |

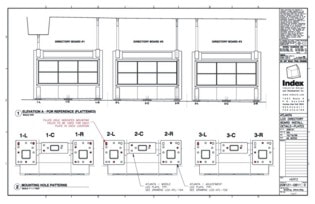

Graphic Displays

LCD monitor display graphic layout configurations are refined based on a 46” monitor size, arrangement and orientation. Color is introduced to the displays through either colored text or subtle background graphics behind the main information. |

Color and Graphic Studies

Simple elevations illustrating the Directory Board in different color combinations were produced using the color palette common to signage in the Hertz facilities: yellow, black, gold & silver. |

Concept Renderings

Renderings and illustrations of the LCD Directory Board concepts are placed in context within a ”styled” Hertz #1 Club Gold Counter area.

Renderings and illustrations of the LCD Directory Board concepts are placed in context within a ”styled” Hertz #1 Club Gold Counter area.

design development

|

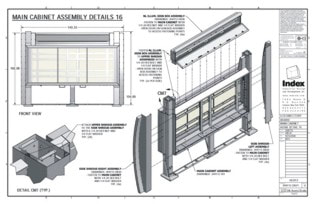

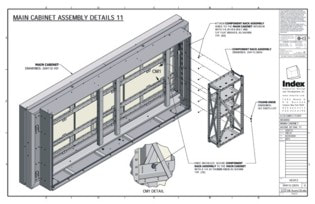

Engineering Evaluation

Component names/designations, part numbers, materials and finishes are assigned to all modeled parts and components in order to initiate a bill-of-materials, review part counts and assemblies, estimate the total weight of the assembled LCD Directory Board, sub-assemblies and individual parts. Weight calculations are also used for structural evaluation to determine point loads and fastening requirements for each installation. |

Product Logistics

The LCD Directory Board is designed to be shipped partially assembled. The main frame assembly is fastened to a custom designed transport apparatus that allows the LCD Directory Boards to be moved into position without machinery. A complete 3D parametric model of the transport apparatus was conceived and produced by IndexID as a transport/mobility, loading, shipment and installation solution for accessibility to final installation locations within Airport Parking Garages. |

prototype production

|

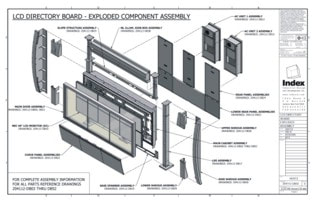

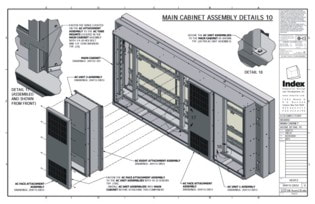

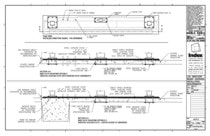

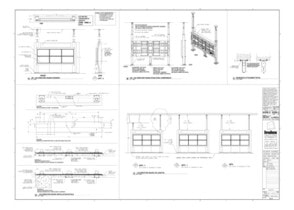

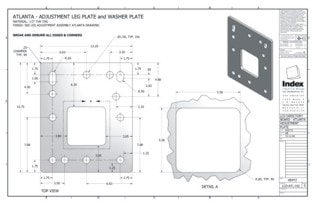

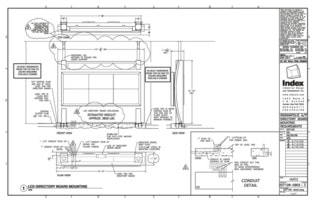

Prototype Drawings

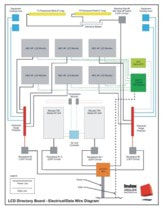

A complete set of prototype production drawings produced from the 3D CAD models; in excess of 200 drawings consisting of 120 parts, 36 sub-assemblies, and specifications for all electrical equipment and controls, computer equipment, monitors, AC units, hardware, gaskets, etc. were included in the prototype document. |

Fabrication

Using the prototype documents and specifications, fabricated components are produced. All components are assembled checking for fit and function. Any necessary adjustments are made to the parts prior to finishing/ powder coating. Revisions are incorporated into all 3D CAD models, and documents. |

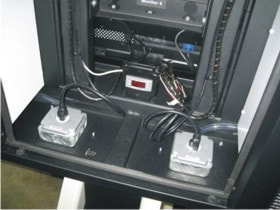

Finished Assembly for Review

Finished components area assembled at IndexID for on-site review and evaluation by Hertz. All components, including monitors, AC units, header signage, and computer equipment were installed and fully functional. |

|

Testing

Performance testing of the LCD Directory Board included in the design and development program. IndexID developed and wrote a test procedure for the LCD Directory Board, contracted with test lab, having an environmental chamber and capabilities to accommodate the scale of the product. A one week plan placed the Directory Board in an environmental test chamber to evaluate the effectiveness of the AC units under varying temperatures and humidity levels The enclosure was also subjected to low and high-pressure water spray to test the effectiveness of the water-resistant seals in the main LCD cabinet.

|

Design Refinement

Revisions were made based on testing results and product evaluation: the AC unit temperature sensors/controls were adjusted to maximize efficiency and, minor changes made to parts for ease of assembly. |

|

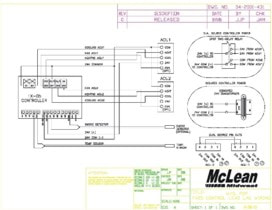

Documentation

Prototype documentation and specifications were expanded into a comprehensive 300+ page Production Document. Supporting documentation which included wiring diagrams, installation instructions, and a maintenance manual was also produced to accompany the prototype document and production packages. |

site installation

|

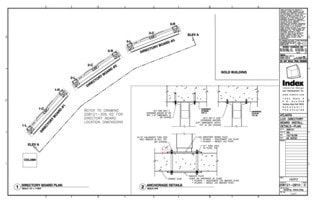

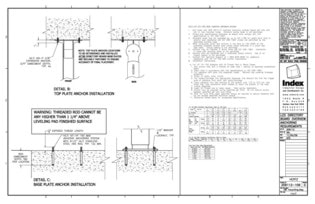

Site Evaluation

IndexID developed plans and procedures for LCD Directory Board installation. Each LCD Directory Board location needs to be evaluated for anchoring, local building codes, wind loads, point loads on garage, and rebar and conduit locations prior to installation. |

Site Specific Modifications

Once the installation site has been evaluated, any necessary part modifications are made and changes to the installation site are coordinated with Airport Engineers and project General Contractors. Changes may be required to move mounting holes to avoid re-bar or conduit in the structure or to compensate for uneven mounting surfaces. |

Delivery & Installation

Each LCD Directory Board was securely wrapped, loaded and delivered to the installation site, located nationally. Once the partially assembled LCD Directory Boards off-loaded, transported, moved into position and securely fastened to the floor and ceiling, the remaining components are assembled and final electrical and condensate line connections are made.

Each LCD Directory Board was securely wrapped, loaded and delivered to the installation site, located nationally. Once the partially assembled LCD Directory Boards off-loaded, transported, moved into position and securely fastened to the floor and ceiling, the remaining components are assembled and final electrical and condensate line connections are made.

Completed Installation